Defective or dull?

Is the cutting performance of your diamond cutting blade declining? That doesn’t necessarily mean it’s defective. Often, it’s simply a case of dulling!

Here, you’ll learn how to restore your diamond cutting blade to peak performance—cost-effectively and efficiently!

Reasons for dulling or blunting

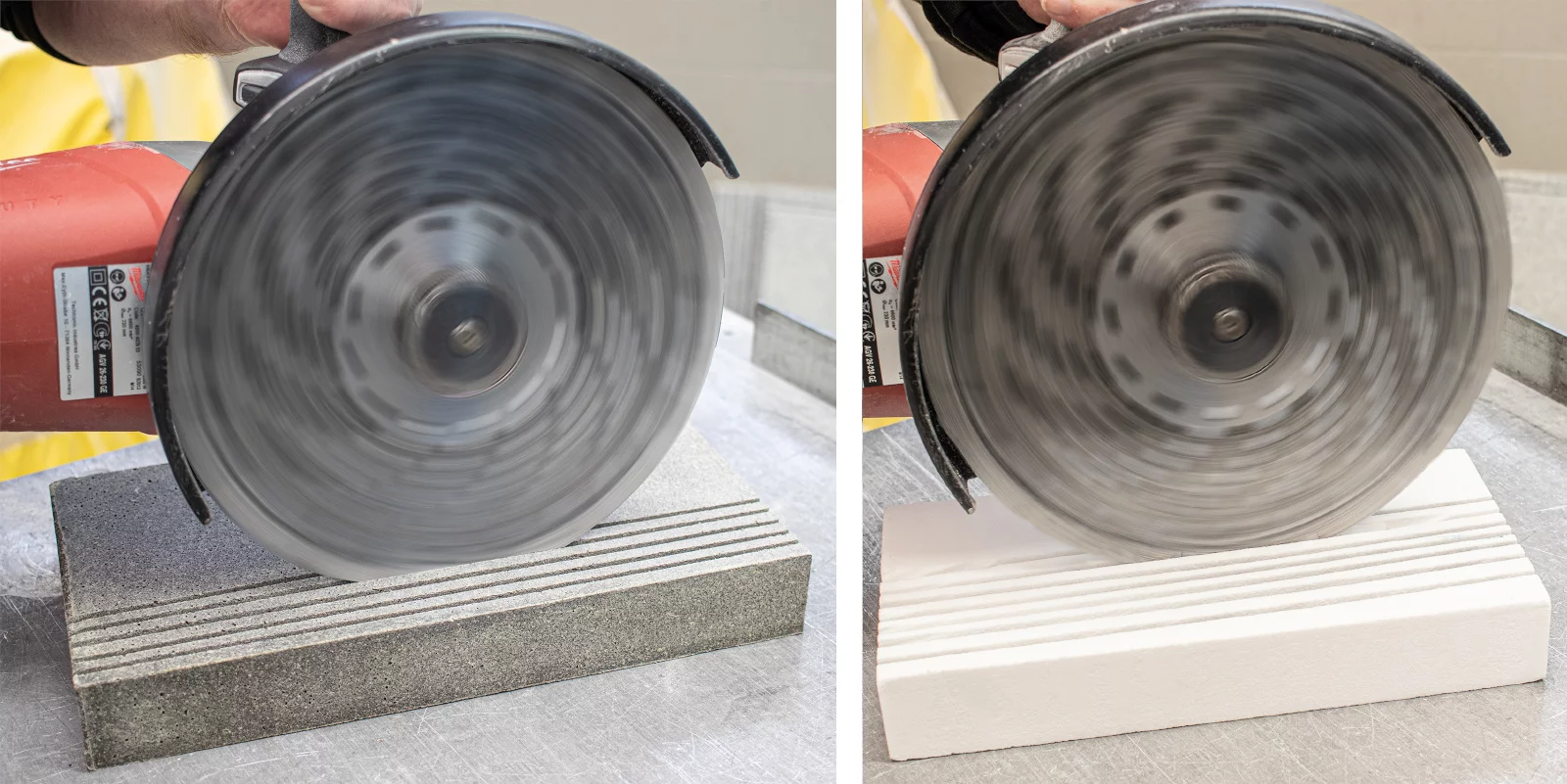

Through extremely hard materials, constant stress, or excessive pressure during cutting or drilling, diamond tools can become dull. However, it is important to know that a dull cutting edge can be re-sharpened using a sharpening plate or sharpening stone. We have the right materials for this and also offer a sharpening guide for you to follow along or replicate!

Please only sharpen DRY!

Perform intensive, shallow precision cuts (only segment height) until the pits are no longer visible.

After a few cuts, turn off the machine and let the blade run out on the sharpening stone with light pressure.

Please repeat this process several times.

The disc is sharpened when new, angular diamonds with supporting tails are exposed. (see fig.)

If the disc becomes dull again after a short cutting time, discs with a softer bond should be used.

If the wear is too high, discs with a harder bond are required, even if this may reduce the cutting progress.