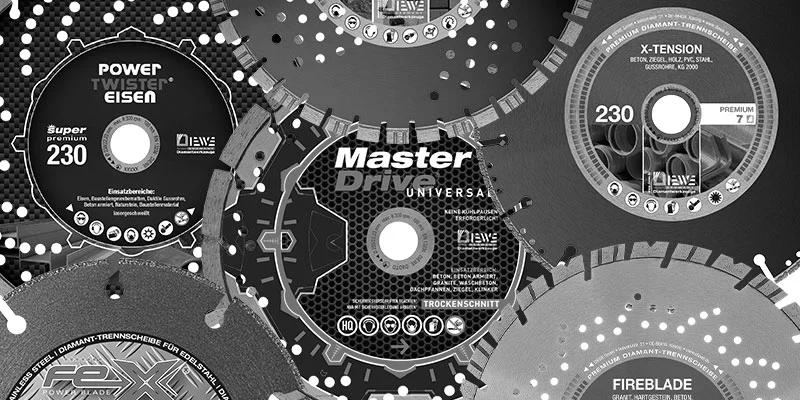

The Diamond Tool – Guarantee for First-Class Work Results

Whether cutting, grinding, or drilling, diamond tools have firmly established themselves in both craftsmanship and industry and are indispensable in any well-stocked toolbox. The advantages of high-quality tools with diamond segments compared to conventional methods are manifold. But what makes diamond tools so special, and where exactly lie the benefits of modern and improved processing technology with diamond tools?

To get to the bottom of this question, a fundamental understanding of the manufacturing and material properties of diamond tools is first required. Using the example of a diamond cutting disc, we will explain the construction and operation of a diamond tool.

The diamond cutting disc consists of a metal base body (the so-called substrate) that is connected with segments embedded with industrial diamonds. It is this industrial diamond that gives the cutting disc its characteristic properties. At DIEWE, we exclusively use synthetic diamonds. These are not only five times more durable and significantly better suited than natural diamonds but also environmentally harmless.

Industrial diamonds are produced using a high-pressure, high-temperature process by compressing graphite in a hydraulic press at temperatures exceeding 1,500 °C and pressures of up to 60,000 bar. Under these special conditions, the graphite transforms into the thermodynamically more stable form of carbon – diamond.

High-quality diamond cutting discs from DIEWE are characterized by impressive cutting speeds and service lives, a special cooling effect, and noise-reducing hole patterns. Depending on the intended application, the quality, geometry, and composition of the cutting disc can be individually tailored to meet customer needs.

- More versatile applications and fewer tool changes

- Higher cutting performance with less effort

- Lower motor power with reduced wear

- Longer runtimes for time and material savings

- Increased productivit

The Comparison:

Diamond Tools vs. Hammer Drills and Jackhammers

In crafts, industry, and trade, drilling, grinding, and cutting tasks are part of everyday life. Whether it involves the precise cutting of tiles, creating circular drill holes in masonry, or accurately sizing roof shingles – the tool is always crucial for the quality of the work outcome.

Compared to traditional methods using hammer drills or pneumatic hammers, diamond tools offer significant advantages. We have clearly outlined these below to facilitate a comparison of both methods:

| Diamond Tool | Hammer Drill/Pneumatic Breaker | |

| Workload | Minimal physical strain | Considerable physical and psychological strain |

| Precision | Clean and dimensionally accurate work | Unclean breakout points due to fractures on surfaces and edges |

| Impact on Concrete Matrix and Reinforcement | Preservation of adjacent structures thanks to a vibration-free working method | Loosening of concrete matrix and reinforcement |

| Environment | Low noise and dust-free | Strong and persistent noise pollution and significant dust generation |

| Costs | Lower costs for closing the remaining cross-section | Increased costs for closing the remaining cross-section |

| Other Characteristics | Unhindered use of adjacent rooms possible without problems | Rapid performance decline with increasing working duration |